You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Big redo of the old bucket

- Thread starter PotvinGuy

- Start date

or this

or this

OK, it is a Google Photos problem. Pardon me while I go get brainwashed to the new order and I will be back someday.

The item above is the centerpiece of my new linkage. I'll post the other images after I take some Vicodin and have a lie-down. If the admin is watching, it sure would be nice if I could edit my posts for an hour or more.

or this

OK, it is a Google Photos problem. Pardon me while I go get brainwashed to the new order and I will be back someday.

The item above is the centerpiece of my new linkage. I'll post the other images after I take some Vicodin and have a lie-down. If the admin is watching, it sure would be nice if I could edit my posts for an hour or more.

Last edited:

I did. It should be an easy change, hope it goes thru.PotvinGuy, did you send Ron a PM?

Jim

Ok, try again. Here is the centerpiece of the new control linkage:

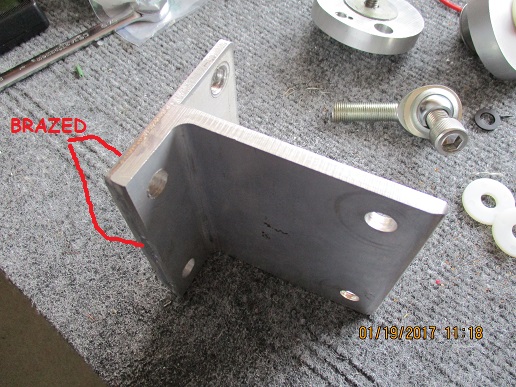

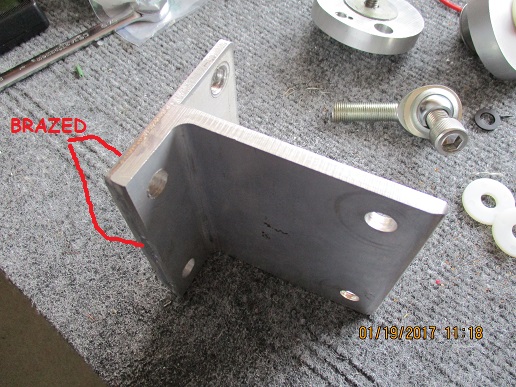

And here is the mount, which attaches to the leaf spring retainer plate:

Note the use of aluminum brazing. This is great if you don't weld. Brazing is done with a propane or MAP torch and an aluminum brazing rod. Both at HD and cheap. Brazing actually binds the pieces together like welding, but it's as easy as soldering. Check YouTube for videos.

And the painted and assembled unit:

Bolt this to perch, add a couple tie rods to the batwings, and see what happens. Have to work around the weather up here in MN; some days I can go for a spin, some days I just sit in a corner and eat a cookie...

And here is the mount, which attaches to the leaf spring retainer plate:

Note the use of aluminum brazing. This is great if you don't weld. Brazing is done with a propane or MAP torch and an aluminum brazing rod. Both at HD and cheap. Brazing actually binds the pieces together like welding, but it's as easy as soldering. Check YouTube for videos.

And the painted and assembled unit:

Bolt this to perch, add a couple tie rods to the batwings, and see what happens. Have to work around the weather up here in MN; some days I can go for a spin, some days I just sit in a corner and eat a cookie...

choppinczech

Well-Known Member

I love hand crafted parts.

I'll have to look into aluminum brazing. There's lots of things where I could use it.

I'll have to look into aluminum brazing. There's lots of things where I could use it.

choppinczech

Well-Known Member

Holy moly, I hadn't even heard of this company! Checking out their site, they build a super cool '32. It ain't cheap, but it is the cat's meow. Very slick Watts and R&P front end.

And if I read it right they are offering a great motor/tranny deal: "a complete, running, low-mileage all-aluminum 4.6L DOHC Ford V8 'Modular' engine with matching 4R70W four-speed overdrive transmission, torque converter, aluminum drive-shaft, and shifter for just $615. This included the wiring loom, ECM, throttle body, ignition coils, starter, alternator, exhaust manifolds, throttle pedal - we even grabbed the radiator overflow bottle."

If they branch out into buckets it would be something!

fletcherson

Well-Known Member

The aluminum brazing is great for thin stuff that typically burns away with a mig. It's possible to repair material as thin as beverage cans. You have to clean well to minimize the heat required and get the best flow. I've found that a broader torch, like a typical propane plumbers torch works well, better than my oxy aceyline torch, because it doesn't over penetrate due to the flame focus.I love hand crafted parts.

I'll have to look into aluminum brazing. There's lots of things where I could use it.

fletcherson

Well-Known Member

Cool idea, you have more faith in aluminum than I for suspension parts, but I guess the load won't be too much. I plan on using a more traditional watts link on mine, a modified speedway offering I picked up. Waiting until I get mine back on the ground to start fitting it under and behind the front axle.Ok, try again. Here is the centerpiece of the new control linkage:

And here is the mount, which attaches to the leaf spring retainer plate:

Note the use of aluminum brazing. This is great if you don't weld. Brazing is done with a propane or MAP torch and an aluminum brazing rod. Both at HD and cheap. Brazing actually binds the pieces together like welding, but it's as easy as soldering. Check YouTube for videos.

And the painted and assembled unit:

Bolt this to perch, add a couple tie rods to the batwings, and see what happens. Have to work around the weather up here in MN; some days I can go for a spin, some days I just sit in a corner and eat a cookie...

choppinczech

Well-Known Member

Nice! I love to see ideas come to fruition.

I got a new handheld (color touchscreen) for my EZ-EFI and it has been a real pain. Constantly resetting, which makes the engine stumble. I tried all sorts of fixes, shielding, grounds, capacitors, etc. Then today I called FAST and they said my ECU firmware was out of date and wouldn't play nice with the new handheld. So I shipped it all to them to be updated. Hopefully when it comes back it will all work. FYI, the latest firmware for the ECU is 238. If yours is older (mine was 233) you might want to get it updated.

Gerry

Well-Known Member

Still thinking about the panhard rod set up. A little bit clever, that one.

Onto the pic below. Is that instrument on the passengers floor permanantly fixed there? Reason I ask is I have been muling over where to put the 2 I have. I did consider on the passengers side either 1/2 way up the side or in the front corner. I guess that anyone sitting in your T on that side would have a leg either side of the dial; not a real problem.

Onto the pic below. Is that instrument on the passengers floor permanantly fixed there? Reason I ask is I have been muling over where to put the 2 I have. I did consider on the passengers side either 1/2 way up the side or in the front corner. I guess that anyone sitting in your T on that side would have a leg either side of the dial; not a real problem.

Yes, I used an A-pillar pod that looked about right and cut it to fit and Bondo'd it to the floor. Seemed like a good place for the tranny temp gauge.

If you have a tranny hump, on top of it might be good.

Here's a pic of the new centering linkage:

...noodle on it for a while and you can see that it is a Watts link made to look better.

If you have a tranny hump, on top of it might be good.

Here's a pic of the new centering linkage:

...noodle on it for a while and you can see that it is a Watts link made to look better.

Similar threads

- Replies

- 3

- Views

- 3K

- Replies

- 0

- Views

- 809