Indycars

Well-Known Member

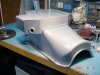

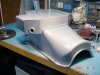

Got all my painting done including color sanding with 800 and 1000 grit paper. Went over it with

polishing compound and then some wax.

Next was to get started on the clean up. I decided to remove the rear main cap so I could get better access

to the grooved gasket surface. The front groove in the timing chain cover had to be cleaned in place. I had

used silicone sealer on both the front the rear grooves, so this took several hours to get properly cleaned.

Pulling the rear main also allowed me to inspect the bearing.

.

polishing compound and then some wax.

Next was to get started on the clean up. I decided to remove the rear main cap so I could get better access

to the grooved gasket surface. The front groove in the timing chain cover had to be cleaned in place. I had

used silicone sealer on both the front the rear grooves, so this took several hours to get properly cleaned.

Pulling the rear main also allowed me to inspect the bearing.

.

Last edited: