PeteT

Member

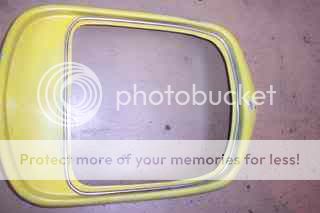

I thought I'd have a go at making an insert for a grill shell I'm going to fit to my new T. It's a chopped 32 glass one. Plan was to try and end up with something like this. I wasn't going to have the insert going all the way down but just to the bottom of the cutout.

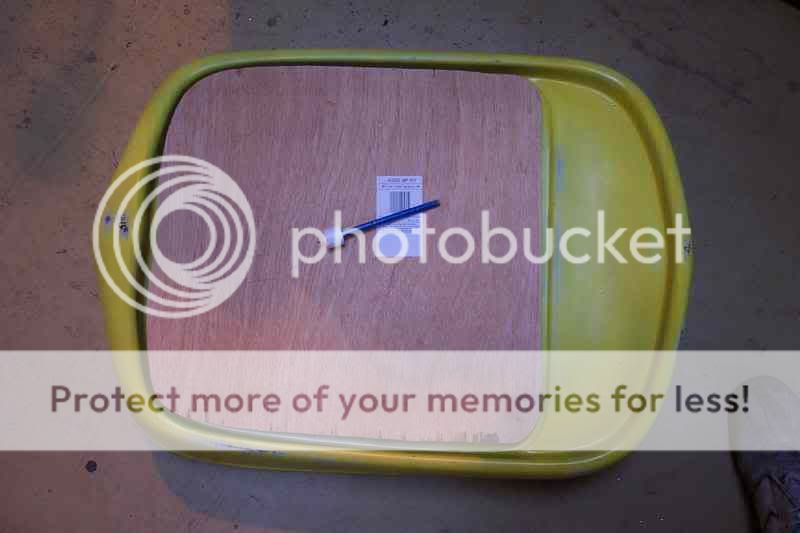

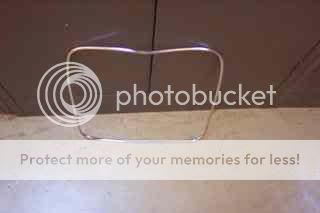

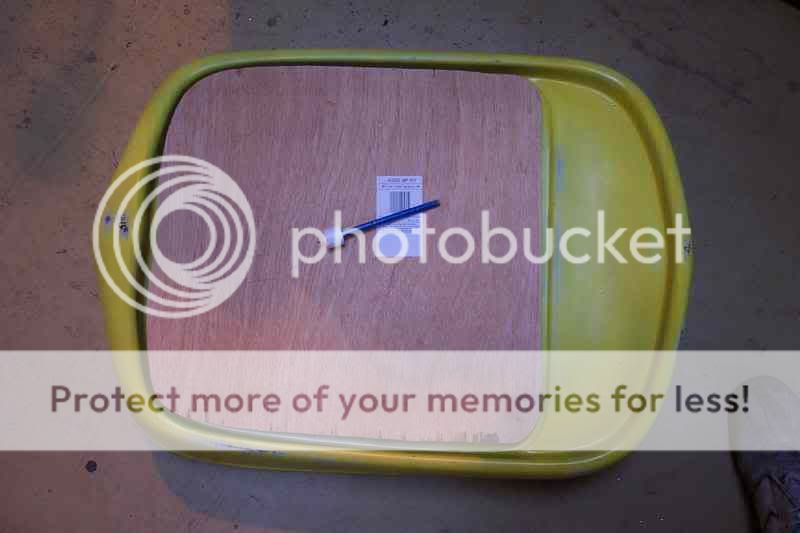

My plan was to make a surround from 5/16 stainless tube shaped round a ply former and weld the join. Then I was going to mill out a quarter section top and bottom (at the rear) so the uprights would fit in. I was going to fabricate the upright as a separate piece by welding/silver soldering the tubes at the very ends. This would then slot into the surround and the welds won't show.

So much for the plan.... I've made a ply former and have tried bending the tube to match but it just kinks. Done a bit of reading and it seems like thin wall tube is very difficult to bend. Did wonder about using solid but it would be too heavy. Also thought of aluminum but I'm not sure my welding is up to that and it also needs load of polishing to keep it nice.

Just wondered if anyone had any suggestions on tube bending or any other ideas for making an insert. I know you guys are full of bright ideas.

Thanks in advance Pete

My plan was to make a surround from 5/16 stainless tube shaped round a ply former and weld the join. Then I was going to mill out a quarter section top and bottom (at the rear) so the uprights would fit in. I was going to fabricate the upright as a separate piece by welding/silver soldering the tubes at the very ends. This would then slot into the surround and the welds won't show.

So much for the plan.... I've made a ply former and have tried bending the tube to match but it just kinks. Done a bit of reading and it seems like thin wall tube is very difficult to bend. Did wonder about using solid but it would be too heavy. Also thought of aluminum but I'm not sure my welding is up to that and it also needs load of polishing to keep it nice.

Just wondered if anyone had any suggestions on tube bending or any other ideas for making an insert. I know you guys are full of bright ideas.

Thanks in advance Pete