Mykk

Active Member

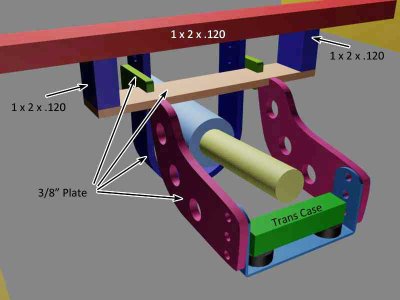

MSpaint skills: The current plan for the frame with the diff perch, gussets, crossmembers and vertical mounts for the fuel tank & steering gear.

Using 1.75" DOM 1/8" wall tubing & 1/4" plate gussets.

For the vertical mounts the 1.75" DOM tubing will be wider then the 1.5" frame, giving me an opportunity to counter sink the tubing into the frame and weld up the inside edge. I'm thinking of also drilling a hole on the outside of the frame and rosette welding the tubing to the frame on the outside edge too.

My plan is to counter sink & rosette weld, as well as surface weld all of the tubing crossmembers and diff perch into the frame.

Using 1.75" DOM 1/8" wall tubing & 1/4" plate gussets.

For the vertical mounts the 1.75" DOM tubing will be wider then the 1.5" frame, giving me an opportunity to counter sink the tubing into the frame and weld up the inside edge. I'm thinking of also drilling a hole on the outside of the frame and rosette welding the tubing to the frame on the outside edge too.

My plan is to counter sink & rosette weld, as well as surface weld all of the tubing crossmembers and diff perch into the frame.