You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wanted Enclosed Car Trailer

- Thread starter Indycars

- Start date

Indycars

Well-Known Member

I hope to complete this project tomorrow while the wind speed is below 10 mph, probably still need some kind of wind break thou. At least it will be easier than a 20 - 25 mph wind we typically have this time of the year.Maybe consider taking some scrap pieces of 1/8" and 1/4" and doing some practice welds with different settings.

Yes you are right about practice, probably spend at least the first half of the day practicing.

Last edited:

Made the 1/4" plate like an elongated hexagon with rounded "corners". Have the height of the plate come out to the radius of the tongue or just shy( ~ 1/8")

D-ring to plate ~140amp (I'm use to stick) Plate to tongue ~70 amps. Is the frame galvanized? You could put some rosettes in the plate too.

D-ring to plate ~140amp (I'm use to stick) Plate to tongue ~70 amps. Is the frame galvanized? You could put some rosettes in the plate too.

Indycars

Well-Known Member

If I understand you correctly, you are trying to get away from any 90° corners with elongated hexagon ?Made the 1/4" plate like an elongated hexagon with rounded "corners". Have the height of the plate come out to the radius of the tongue or just shy( ~ 1/8") D-ring to plate ~140amp (I'm use to stick) Plate to tongue ~70 amps. Is the frame galvanized? You could put some rosettes in the plate too.

Height of the plate and radius of the tongue, not sure what you mean ?

Frame is not galvanized unless they painted over it. Are you thinking about the toxic gas it creates ?

Rosettes are a great idea, this is the kinda of idea I was hoping for. Something that I had not thought about. I think I can get a couple of them on two sides (4 total) or make another plate with more room. Although I'm thinking that the weakest point is going to be the D-Ring mount to the plate and not the plate to the tongue. But when given an option to make anything stronger, I will go that direction.

Greatly appreciate your comments !

Last edited:

I assume you are talking about MIG welding. I would use the 1/4" settings on your welder as a starting point (if it has a table or some other recommendation). Start by tacking the pieces together, then begin the weld on the 1/4" material, move the puddle up or down to the 1/8" and proceed. You can find all the advice and videos you will ever need here Welding Tips and Tricks - TIG, MIG, Stick and a pantload of other info

fletcherson

Well-Known Member

Hotter is my thought, spread the puddle, not just a bead. Use the arc to blend the steel. When I weld heavier pieces to lighter, I start on the heavy and blend to the thin, if that makes sense to you. Good ground and prep is helpful.

mountainman

Member

Getting ready to weld on the D-Rings to the tongue on the trailer. I'm far from a good welder, so I'm trying to give myself the best chance of success. Instead of welding the D-Ring directly to the tongue,

I'm thinking that welding it to some 1/4" plate first where I can be in the most comfortable position

and then welding that plate to the tongue. This way I get to put a weld on all 4 sides and spread the

load out. Sound right ?

Comments ?

View attachment 18798

.

It is obvious by your choices throughout this thread that you are wanting this trailer to be the highest quality possible. In view of your upgrading the safety chains to the level that you have, why would you not get a professional welder to weld the D-rings on? You have admitted you are not a great welder and not sure of the best method to give yourself "the best chance of success". That would be a professional welder with the fabrication knowledge in this area. No "good enough" at this stage.

Indycars

Well-Known Member

Yes, sorry forgot that important detail!I assume you are talking about MIG welding.

Yes, I really enjoy Jodie at "Tips and Trick". He speaks well and his video of the actual weld puddle are extremely good.

Thanks !

Last edited:

choppinczech

Well-Known Member

Indycars

Well-Known Member

That sounds like would be over kill which I'm not against most of the time. But I only have so much room at the front nose of the tongue. To install something that large would have to be moved back too far.I meant for the height, you have a 2 x 6 rectangle tubing, 6" on the vertical. How much of a radius is on the corners of the tongue? 1/4"? 6"- (2x1/4") - 1/8"= plate height of 5 3/8". As far as the width, I would make it ~ 10-12" across the rounded points.

Last edited:

Indycars

Well-Known Member

That seems to be my plan of attack. More than one person has suggested something very similar.Hotter is my thought, spread the puddle, not just a bead. Use the arc to blend the steel. When I weld heavier pieces to lighter, I start on the heavy and blend to the thin, if that makes sense to you. Good ground and prep is helpful.

Indycars

Well-Known Member

That has crossed my mind, but for some reason it got pushed aside until you brought it up again. I texted someone I worked with at Advance Auto who is a full time welder, I don't know how much MIG he does. Since it vessels for the oil field, I'm guessing it might be more stick welding. It's been 30 minutes and so far I have not heard back from him.You have admitted you are not a great welder and not sure of the best method to give yourself "the best chance of success". That would be a professional welder with the fabrication knowledge in this area. No "good enough" at this stage.

Last edited:

Indycars

Well-Known Member

I'm thinking it would be too far back from the nose of the tongue. Also I would have to bolt thru the 2" dimension of the tubing, but I guess that's what the extra plates are for.

You are looking up at the bottom side of the tongue where the three 2" x 6" tubes come together and the tongue jack in the middle.

Last edited:

fletcherson

Well-Known Member

If you ever had a trailer come unhitched, you will have a new appreciation for chains. I had a restored speed boat come off while I was accelerating down a freeway entrance ramp... somehow the latch pin disappeared. Thankfully, the chains held and I was able to just push the clutch in and coast to a stop... it was a serious awakening.

Indycars

Well-Known Member

Edgar did answer my text before I even got started with some practice. So he came over and was here in about an hour. I paid him $50 for his welding and he also did some grinding and a few other details. I had some 1/8" and 1/4" plate for him to get the welder setup to his liking before he got started with the D-Rings.

He decided to weld the plates on the tongue first and fill in the plug welds (4 per plate), then he did the D-Rings.Just opposite of what I was planning for myself.

Right Side

Left Side

.

He decided to weld the plates on the tongue first and fill in the plug welds (4 per plate), then he did the D-Rings.Just opposite of what I was planning for myself.

Right Side

Left Side

.

Last edited:

Indycars

Well-Known Member

Thanks Mountainman for getting me back on track !It is obvious by your choices throughout this thread that you are wanting this trailer to be the highest quality possible. In view of your upgrading the safety chains to the level that you have, why would you not get a professional welder to weld the D-rings on?

Last edited:

old round fart

Well-Known Member

That should hold it!!! He did good!

Indycars

Well-Known Member

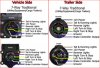

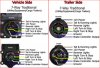

I've had the trailer since April 6th and I just got around to checking out the 12 volt dome and load lights, they didn't work. All my brake, turn and running lights did work. I applied 12v to the Trailer Battery Charge Wire, my dome and load lights worked then. I knew the problem was with my 2008 Lincoln Navigator, so I broke out the 9,000 page (Digital) factory service manual to see what I could figure out.

The ignition switch has to be in the run position. Even thou my 2008 Lincoln Navigator has a $600 Trailer Tow Package, they did not supply a relay and a 30 amp fuse needed for the battery charge wire. Any standard rely will work, you don't need the "Ford" relay.

The two locations noted below were empty !

On the vehicle 7 pin connector, the battery charge wire is shown below.

.

The ignition switch has to be in the run position. Even thou my 2008 Lincoln Navigator has a $600 Trailer Tow Package, they did not supply a relay and a 30 amp fuse needed for the battery charge wire. Any standard rely will work, you don't need the "Ford" relay.

The two locations noted below were empty !

On the vehicle 7 pin connector, the battery charge wire is shown below.

.

Last edited: