You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

In need of Help..

- Thread starter Space Coast Rodder

- Start date

Space Coast Rodder

Member

With some parts installed wrong & some parts missing it makes me want to convert to disc even more..If I'm seeing correctly , that looks like a GM pinion snout , if that's the case then someone left out the self adjusters , the other observation is that those adjusters are really cranked out , maybe drum ground oversize ??

fletcherson

Well-Known Member

The lack of a proportioning valve wouldn’t cause the hard petal issue that you described. I would think that is caused by incorrect petal ratio, incorrect master bore, pinched line, maybe residual valve installed backwards, but that’s a stretch. Be sure the mc is plumbed to the correct axles. I would inspect and adjust everything, be sure you have good fluid flow to the wheel cylinders and calipers, paying particular attention to the petal ratio first, then the mc bore size. Once you get acceptable petal reaction and feedback, you can do some test hard stops to determine if the bias needs addressing. Some guys don’t use any proportioning valves, some install adjustable on the fronts, some on the rears... it depends on your particular build. Your parts should have part numbers on them, the internet might help identify your components. If you have to swap the master, it’s not a very expensive piece, so even if after swapping it you decided to go a different route, you shouldn’t be out too much... these things are never finished anyways! Hobby!I certainly won't change anything at this point. The thing is, I also don't want to change things out to get this system working only to find that I need to change again for the conversion... You are correct in saying I have no clue about the parts used so I'm going to try & post pics of what I have & maybe someone can help me identify everything.. Also I can't find a proportioning valve anywhere, should my set up have one installed ? My problem is also compounded with the fact that I'm a Brit now living in Florida & have little experience with American cars & parts.. Many thanks to everyone for the help..Hope I can now post pics..

fletcherson

Well-Known Member

The lack of a proportioning valve wouldn’t cause the hard petal issue that you described. I would think that is caused by incorrect petal ratio, incorrect master bore, pinched line, maybe residual valve installed backwards, but that’s a stretch. I would inspect and adjust everything, be sure you have good fluid flow to the wheel cylinders and calipers, paying particular attention to the petal ratio first, then the mc bore size. Be sure the mc lines are going to the correct axle. Once you get acceptable petal reaction and feedback, you can do some test hard stops to determine if the bias needs addressing. Some guys don’t use any proportioning valves, some install adjustable on the fronts, some on the rears... it depends on your particular build. Your parts should have part numbers on them, the internet might help identify your components. If you have to swap the master, it’s not a very expensive piece, so even if after swapping it you decided to go a different route, you shouldn’t be out too much... these things are never finished anyways! Hobby!

Space Coast Rodder

Member

I'll find out the pedal ratio today & if that's ok I'll pull the master cylinder later in the week & go from there.. I already checked for a pinched pipe and didn't find a problem..The lack of a proportioning valve wouldn’t cause the hard petal issue that you described. I would think that is caused by incorrect petal ratio, incorrect master bore, pinched line, maybe residual valve installed backwards, but that’s a stretch. Be sure the mc is plumbed to the correct axles. I would inspect and adjust everything, be sure you have good fluid flow to the wheel cylinders and calipers, paying particular attention to the petal ratio first, then the mc bore size. Once you get acceptable petal reaction and feedback, you can do some test hard stops to determine if the bias needs addressing. Some guys don’t use any proportioning valves, some install adjustable on the fronts, some on the rears... it depends on your particular build. Your parts should have part numbers on them, the internet might help identify your components. If you have to swap the master, it’s not a very expensive piece, so even if after swapping it you decided to go a different route, you shouldn’t be out too much... these things are never finished anyways! Hobby!

Driver50x

Member

The missing adjuster hardware is nothing but a minor issue. You can adjust the brakes by hand anyway. You can buy the adjusters at any auto parts store if you want them. Your springs are installed correctly. You really need to measure your master cylinder piston size. As others have said, that could very likely be your problem. Even on a car as light as a T-Bucket, the cylinder sizes make a big difference. You can probably measure it without removing it from the car, depending on how it is mounted. Just pull back the rubber seal and use a tape measure.

Neshkoro

Well-Known Member

DFriver50X, it was my understanding that the coiled part of the spring goes over the star wheel to help hold it in adjustment.

When there is an adjuster, like what Choppedtop showed, the spring is installed with the coil away from the star wheel. But when there is no adjuster mechanism the spring goes the with the coils over the star wheel.

Just sayin'.

When there is an adjuster, like what Choppedtop showed, the spring is installed with the coil away from the star wheel. But when there is no adjuster mechanism the spring goes the with the coils over the star wheel.

Just sayin'.

choppedtop

Well-Known Member

Yeppers, something has got to make contact with the star wheel. If not adjustments would not stay to the proper tightness.

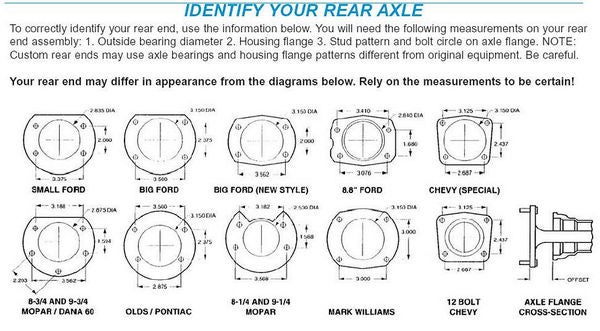

Did the "Tri Fives" have self-adjusting brakes? Is it a Chevy RR or a 8 3/4" Mopar? What's the wheel bolt pattern? Can you take a pic of the pumpkin?My first bucket has a '57 Chevy rear end. Looked much like that one

Jim B

Active Member

Putting discs on the rear may actual!y decrease your brake performance , you're going to have to figure out what parts are on there now.. pictures so we can help .. think of ten words , make ten separate 1 word posts ,then you!l be able to post pics ...

2old- I already have a complete rear end with discs ready to go. Why would rear drum brakes improve braking performance over disc brakes?

old round fart

Well-Known Member

Takes more pressure to make disk brakes work.

Jim B

Active Member

gotcha! good point.Takes more pressure to make disk brakes work.

2old2fast

Active Member

Tri five did not have self adjusting , that started about 63 ??Did the "Tri Fives" have self-adjusting brakes? Is it a Chevy RR or a 8 3/4" Mopar? What's the wheel bolt pattern? Can you take a pic of the pumpkin?

Another point about drums vs. disc is the E brake , it's self-contained on drums ,looks like some add on most discs ..gotcha! good point.

Neshkoro

Well-Known Member

Either disc or drum brakes are more than adequate to stop your bucket as long as everything is working correctly. Working correctly is the key. Disc brakes have some advantages over drums. For instance: brake fade, wet operation. Discs have the cool factor. Drums are old technology Its like having a distributor with points vs. an electronic distributor. Either one will do the job.

Space Coast Rodder

Member

I'll be changing to discs soon, I prefer the look of them by far.. Haven't made much progress over the last few days, I can't seem to shake the bug I got & I just don't feel like working on the car.. Hopefully this will clear up soon Then I can get into sorting all this out.. Many thanks to everyone who's been helping along the way..Either disc or drum brakes are more than adequate to stop your bucket as long as everything is working correctly. Working correctly is the key. Disc brakes have some advantages over drums. For instance: brake fade, wet operation. Discs have the cool factor. Drums are old technology Its like having a distributor with points vs. an electronic distributor. Either one will do the job.

Similar threads

- Replies

- 57

- Views

- 23K