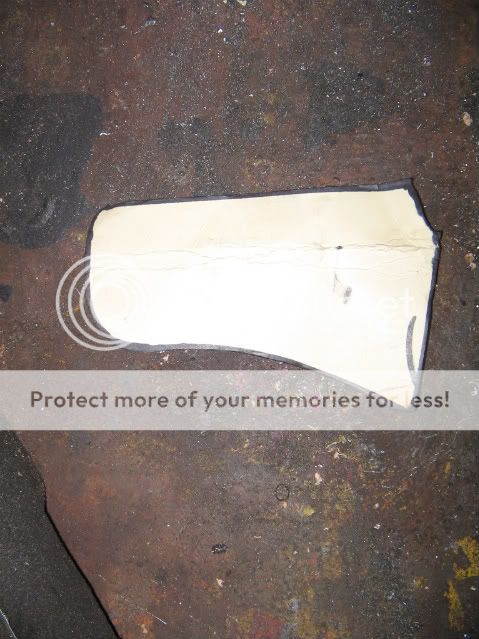

Come up with a design you like, trace it our on paper, thin cardboard

Trace it to your steel, I'm using 1 x 2 1/2 rec. tubing.

Whittle it out, using what ever you have bandsaw,cut off wheel, plasma cutter.. I used a 4" electric grinder and dressed it out with my belt sander.

Create a template for the foot of the bracket,set your angle, mine is set at 80 degree's., I also drew a bunch of circles on them triying to come up with a speed hole design I liked..Once i found a design i broke out the dial caliper's and measured, marked and started drilling....

finish welding, grind and sand, ready for prime and paint

side angle

mounted on cowl, time to make a center bracket...Another day for that....

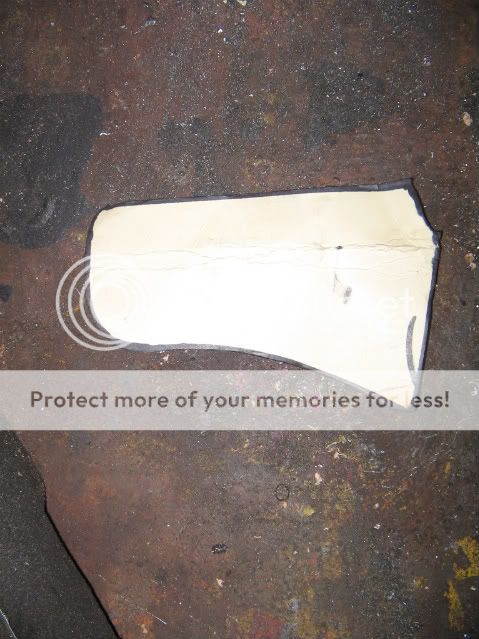

Trace it to your steel, I'm using 1 x 2 1/2 rec. tubing.

Whittle it out, using what ever you have bandsaw,cut off wheel, plasma cutter.. I used a 4" electric grinder and dressed it out with my belt sander.

Create a template for the foot of the bracket,set your angle, mine is set at 80 degree's., I also drew a bunch of circles on them triying to come up with a speed hole design I liked..Once i found a design i broke out the dial caliper's and measured, marked and started drilling....

finish welding, grind and sand, ready for prime and paint

side angle

mounted on cowl, time to make a center bracket...Another day for that....