You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Silver bolts

- Thread starter Paulski

- Start date

Track-T

Active Member

Or to put another way.....

Let’s look at an example of where grade 5 and grade 8 bolts are subjected to single shear loads (winch plate reference).

Using a .250-inch diameter grade 8 fastener gives you the following shear capability:

A = Cross-sectional area of the fastener size (since bolt bodies/shanks have circular cross-sections, use area of a circle) = Pi x r2 where R (radius) = .250/2 = .125, therefore A = Pi x (.125)2 = .0491 square inches (in2)

Capability in shear = 91,000 lbs / in2 x .0491 in2 = 4468 lbs

Using the same .250-inch diameter grade 5 fastener results in the following:

Capability in shear = 75,000 lbs / in2 x .0491 in2 = 3683 lbs

That’s a difference of over 750 lbs or over 1/3 ton. In this example you can clearly see that using a grade 8 fastener has a superior advantage over the grade 5. Therefore the result is if someone is using grade 5 bolts in a shear application like the winch plate example, they will fail almost 800 lbs earlier.

Let’s look at an example of where grade 5 and grade 8 bolts are subjected to single shear loads (winch plate reference).

Using a .250-inch diameter grade 8 fastener gives you the following shear capability:

A = Cross-sectional area of the fastener size (since bolt bodies/shanks have circular cross-sections, use area of a circle) = Pi x r2 where R (radius) = .250/2 = .125, therefore A = Pi x (.125)2 = .0491 square inches (in2)

Capability in shear = 91,000 lbs / in2 x .0491 in2 = 4468 lbs

Using the same .250-inch diameter grade 5 fastener results in the following:

Capability in shear = 75,000 lbs / in2 x .0491 in2 = 3683 lbs

That’s a difference of over 750 lbs or over 1/3 ton. In this example you can clearly see that using a grade 8 fastener has a superior advantage over the grade 5. Therefore the result is if someone is using grade 5 bolts in a shear application like the winch plate example, they will fail almost 800 lbs earlier.

The same theory of it is better to bend than break is used there too.

My theory is that it's better to choose a fastener which does neither.

Bob

bucketkids

Member

Guess I'll start changing out all my plastic wire ties!!! Pass the pop corn. With X-Junk stainless. It aint let him down yet and he don't own a trailer. (for the T)

Brucer

New Member

Its about to get even better

Well since we are discussing car suspension, and not tool and die making, Brucer, how about we stick to info that is relavent to that ? Tensile strength has very little to do with this. Most all fasteners used in the suspension of the type of car we building, are in shear. And a lot are single shear at that. Grade 8 vs. Grade 5 is the same as chromemoly vs. Mild steel. One is more forgiving that the other. Mild steel will bend in situations where chromemoly fails. Same with the grade 5 bolts compared to the grade 8 bolts. And in a suspension system (as well as steering systems), that ability to bend, rather than break, is more desirable. Look at these pictures, specifically the bolts holding the front bars to the frame.

This is a typical set up. Whether it is a four bar, radius bars, split wishbones, they are almost always mounted in single shear. The constant pounding those fasteners take, will break a grade 8 bolt. But only bend a grade 5. That pounding is the vibration I was talking about. Maybe vibration was the wrong word to use. Flexing is probably the proper term. It is just not vibrating, there is force behind it also. That flexing will work harden the steel. No heat required. Dont believe me, go grab a piece of metal, or as I learned with as a kid, a coat hanger. Start bending it back and forth. What happens ? If you do it fast enough, it generates its own heat... And it will eventually crack.

Here are some quotes to support this found thru a google search...

"Fatigue in a fastener can cause sudden, unexpected failures. A fatigued fastener can fail even when loads are below the strength of the material due to operating under constant cyclic loads. Fatigue strength is often defined as the maximum stress a fastener can withstand for a specified number of repeated cycles before it fails."

"One of the issues with Grade 8 bolts is that there are some areas where you really don't want to use them," says Doc Hammett, Totally Stainless. "If there's a cycling load on them you could start to get into trouble."

There is no doubt grade 8 bolts are stronger than grade 5. But does the strength difference matter in this application ? A 1/2-20 grade 8 bolt has a tensile strength of 150,000 psi. The same grade 5 is 120,000 psi. Shear strength is estimated at 60% of tensile strength. The shear strength of a 1/2" bolt is approx 14,130 psi. Do you really think the rating of that grade 5 is not enough to hold up your 2000# car ? If you dont, going up to a 5/8-18 grade 5 would be better than going to a 1/2-20 grade 8. More strength and more forgiving. 17,662psi for the 1/2" grade 8 vs. 22,078 for the 5/8" grade 5. (assuming my math was correct LOL). And who is to say a 1/2" bolt in this app isnt overkill already ?

A question I always have for the guys that swear by grade 8's is why stop there ? Why not L9, why not air frame bolts ? I believe the simple answer is the others are not easy to get. A grade 8 is available at your local, home depot, lowes, ace hardware. But does any one stop to question the quality of those grade 8's ? NO. We all know the chinese are good for importing low quality products. Don't you think thier fasteners could be the same ? There steel is known to be poor quality. Now what about the quality of grade 8 vs. The aircraft hardware ? A lot of high dollar race cars use aircraft hardware. Not grade 8's. So is it safe to assume it is better ? I think so. The tensile strength of an air frame bolt is similar to that of a grade 5 (the online sources I found for AN hardware says 120,000-125,000 psi). The same theory of it is better to bend than break is used there too.

There is a lot of good advice on the internet. There is also a lot of bad advice. The problem is separating the two. The worst advice, can sometimes make the most sense to someone who doesnt have any knowledge on a subject. Do your own home work, spend a little time on google doing searches, and apply some intelligent thought to all you read.

lke,

thats all good, and technical, i can pull out a machinist handbook and point out where it says, when you tighten a bolt to torque specs you effectvely reduce its strength near 30% ..

So i'll add, do you use a torque wrench? if you do you are reducing the strength of a grade 5 bolt by 30% if your not using a torque wrench your reducing its strength even more, most of the time you will over tighten a 1/2bolt using a handwrench.. not to mention the *shear* strength that you mention applies to the threads also, which everyone knows the threads are the weakest point of a bolt.. thread engagement is the critical factor.. softer steel equals weaker threads, this is the main factor to me .. and when torqued they are even weaker.. why do you think engines are built with grade 8 bolts? its not shear they are worried about , its stretch and thread engagement. Suspension components you will have side load, which generates stress on threads also.

why do you think all rear suspension kits sold have 5/8 or bigger bolts in them and fine threads, its exactly as you stated.. yet have i bought a suspension kit with a grade 5 1/2inch bolt in it, nope i havent, and i've bought and installed a few and also made a few in my day..

i can go one farther, go to page 1278 in the 23rd edition of the machinist handbook.. it will explain it perfectly. i can take a picture of the page and post it, if you want.

the fastest vehicle i built ran a 6.10 in the 1/8, i used grade 8 bolts on the rear ladder bar mounts. the 5/8 holes in the front ladder bar brackets elongated ,the 5/8 fine thread grade8 bolts didnt break..

i'll use grade 8 for the strength of the threads alone. especially on a street car where side loads are experienced..

Screaming Metal

Active Member

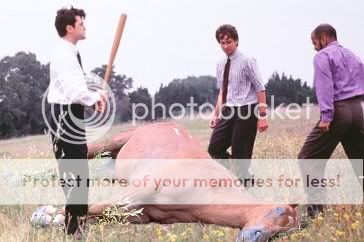

Here ya goand a Dr Pepper

:sos:

Man....have we beat this horse or what?????OK...DR1 Chassis and several others use grade 8's....

Me...I build racing stuff.... alot of the brackets are made GOOD steel on the frontends....all the clevises and heims are 4103 and 4140....same stuff axles are made from.

Alot of the guys won't use cut threads but rolled, hi tensil strength grade 8 bolts....the more exotic stuff titanium....

Singe shear, if the hole dia. is tight, will shear a strong bolt, with a good bit of pressure.

Then you got double shear....yada, yada,yada.....

With (4) grade 8 bolts in the wingplates on your front axle, you got 4 bolt that together can withstand 60,000+ psi. Now....I'm being conservative there....look into a Machinists Handbook! You got springs on these cars, the holes aren't super tight, and the wingplates aren't made from 4130 or 4140....just 3/8 cr a36 grade plate on a car thats got air in the tires and 2400 at the most. We're not talking about me walking out into my shop and sicking these bolts into my 55 ton Ironworker....which won't flinch at 3/4 grade 8....its got super hard jaws and serious tonnage.

I'm with RPM, VegaBruce and Brucer and the other guys.....your not stressing these bolts enough to worry about.

Wanna worry? What about your u-bolts on the rearend? They're usually not grade 8's....usually a annealed style of grade 8 or a grade 8 that has been drawn down...

Mant Mucho stress??? Driveshaft bolts! Hey....they're grade 8....

Go check out Mark Williams Chassis or DR1 frames....look at some of their suspension stuff.

Don't worry.....if ya wanna change bolts, change bolts. If ya wanna get super technical....put in a grade 10 or 12.....that way you'll have about 40,000 psi safety margin per. :woops: :hoist: :sos:

Screaming Metal

Active Member

Now how did that sillystuffpop up there?

Screaming Metal

Active Member

Track-T....You da Man! Ha! :hoist:

Look like what I found...

http://www.nationaltbucketalliance.com/tech_info/Generalinformation/fasteners/ntba_bolt_chart.asp

and a quote from there... "Use extreme caution when selecting suspension fasteners. These fasteners are subject to harmonic shock and vibration. Harder fasteners tend to snap under these conditions.

NOTE: The suggested T Bucket applications are based on years of trial and error by builders of street rods and race cars. History has shown that grade 8 fasteners used on suspension components have a very high failure rate. The NSRA and the NHRA will not pass a vehicle which uses grade 8 in suspension. "

Interesting...

Be carefull choosing what race cars use for you street car. The upkeep performed on a 300 mph race car is a little different than what the typical T gets. And i seem to remember all the really fast race cars I have seen, whether it is drag or indy, used what looked like air craft hardware. And I touched on that earlier.

http://www.nationaltbucketalliance.com/tech_info/Generalinformation/fasteners/ntba_bolt_chart.asp

and a quote from there... "Use extreme caution when selecting suspension fasteners. These fasteners are subject to harmonic shock and vibration. Harder fasteners tend to snap under these conditions.

NOTE: The suggested T Bucket applications are based on years of trial and error by builders of street rods and race cars. History has shown that grade 8 fasteners used on suspension components have a very high failure rate. The NSRA and the NHRA will not pass a vehicle which uses grade 8 in suspension. "

Interesting...

Be carefull choosing what race cars use for you street car. The upkeep performed on a 300 mph race car is a little different than what the typical T gets. And i seem to remember all the really fast race cars I have seen, whether it is drag or indy, used what looked like air craft hardware. And I touched on that earlier.

Lee_in_KC

Active Member

I think we're all being quietly converted to... Scotsmen!!!RPM...Where'd you get a drum from under your name?

(Mike.. my mother's grandfather's name is Robert Bruce Davidson!)

Lee_in_KC

Active Member

I mean from personal experience... not what you heard or read somewhere.Can anyone on this forum cite a single instance of a bolt failing in a front suspension of a hot rod... ever?!?!?

one finger john

Active Member

hey all, If I remember correctly, there was a big discussion on the HAMB 'bout suicide front ends and a broken spring hanger. Had pictures. Most bolt failures haven't been breakage, been wear thru the shank, or threaded area. Or rusty, old, I wouldn't run 'em , bolts that were ill fitted for the job. Usually when left loose way too long.

As a side note, I appear to have a parrot on a surfboard below my name. what is it really?

John

As a side note, I appear to have a parrot on a surfboard below my name. what is it really?

John

Screaming Metal

Active Member

I mean from personal experience... not what you heard or read somewhere.

A couple.....once before Don Garlets got into his rear engined digger.....there was a guy at the same track....hooked up too well....stood it straight up....the guy hit the brakes...down it came...broke a couple of bolts....you get the idea.

The other was a A/Altered, the bolt broke after the run on the return road....it'd been in service for about 8 years.

These were about 6 or 7 years apart....don't happen all that often.

Screaming Metal

Active Member

I just have to wonder what NHRA says about front steering and suspension bolts?

I wonder if is says all Top Fuel cars must run grade 2 or 5 bolts in the front end, or the rear wing struts? Anybody got a current NHRA rule book?

Just wondering

Well Ron, the rulebook doesn't elaborate on the fasteners, too much....but have designs that the pro frame makers have to strickly adhere to. The designers of the frames design them to run in certain classes with certain constrains, wheelbases, weights, Certain engine sizes, certain fuels.

Now, the engineers design a frame thats safe, it gets approved by the committee at the NHRA.

Now...since all this stuff is really hush-hush.....I'm waiting for FluidFloyd to join in in a moment.

The NHRA changes its rules so much....you can run perfectly legal one race, load up, go acress the country....and they've amended the rule at the next race track....so your illegal.

You gotta go thru tech inspections though....and they say grade 8 bolts, better have grade 8's!

Hey George.....my rulebook is locked in my file cabinet at the shop.....what your take? Over at JD1, (which I refered to as DR1 earlier....sorry), grade 8 or any equiv. psi rated hi strength fastener....as per the manufacturers engineering specs. are acceptible.

Now, if you custom build your own....its gotta meet very strengent specs and they have to signoff on it, before you put a bunch of stuff on it. The send inspecors to check it out. Put it like this....its almost to where its not fun anymore.

Similar threads

- Replies

- 43

- Views

- 10K