This weekend I did some experimenting with a T that has a frame built from the plans I have posted in the Tech Articles here.

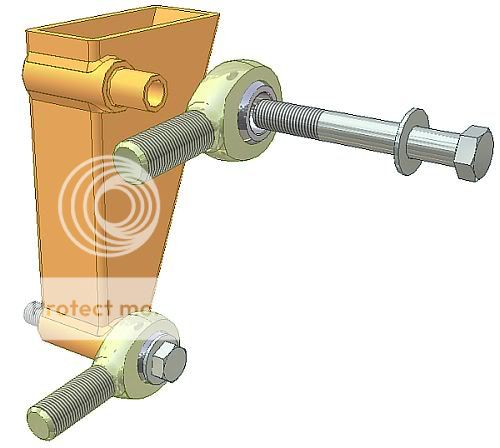

We swapped the bushed ends on the ends of the hair pins for heim ends. Although there didn't seem to be a problem with the bushed ends, I have always wondered if the heims wouldn't work better. As a result, we found the steering effort to be less with the heims on an unequal road surface. I don't think I would go as far as to say the ride quality was improved. At least I didn't notice any change during a 60 mile test drive.

The parts used were ordered from Speedway.

Heims...#175-0126

cone spacers...#546-4110

It should be noted here that a washer should be installed on the outside of the heim as a safty item incase of heim failure. We used a cone spacer for the washer to increase the articulation of the heim.

Ron

We swapped the bushed ends on the ends of the hair pins for heim ends. Although there didn't seem to be a problem with the bushed ends, I have always wondered if the heims wouldn't work better. As a result, we found the steering effort to be less with the heims on an unequal road surface. I don't think I would go as far as to say the ride quality was improved. At least I didn't notice any change during a 60 mile test drive.

The parts used were ordered from Speedway.

Heims...#175-0126

cone spacers...#546-4110

It should be noted here that a washer should be installed on the outside of the heim as a safty item incase of heim failure. We used a cone spacer for the washer to increase the articulation of the heim.

Ron