old round fart

Well-Known Member

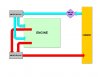

I have been spending time in the shop. I have the new rails made and ready to reattach at the firewall. The chassis is back up on the table and all the braces to hold everything are cut and ground at edges to hold front end steady and brackets to hold rear rails where they need to be. Then another design change! I’m going to run my water through the flame rails so before I attach it I need to be sure it’s watertight. I’ll go get pipe bungs to put in the bottom of the frame at the firewall so I can drain radiator and check for leaks. Cool water will be in right rail and return water in left rail.