A lot of things touched on in this thread that grab my attention........

I've never seen a sway bar on a T-bucket either. My whole rear suspension will be unusual for a T...a triangulated 4 link from a Fox body Mustang road racer, modified to use axle mounted airbags instead of lower link mounted coils. The suspension came with a lower link mounted sway bar. I have no idea if it will be of any benefit on a T-bucket. I'm going to try it with and without the sway bar, and if there is no noticeable degradation without, I'll be leaving it off. I do not care for the cluttered look with it on.

On the front, I'll be running a 4-bar setup with a very low and parallel to the axle +-24" Panhard bar. I have no idea if there would be any benefit to some form of sway bar...and no clue to how to set one up. I do know that the Welder Series site has DIY lever action sway bar components.

I'll be cutting out a wood reinforced driver side door on mine. I think & hope I have a neat way to do it based on a method RPM wrote up somewhere quite a while back. It uses wood bonded into the body, overlapping the eventual cutout lines. The cuts are made through the fiberglass and wood, leaving perfectly matched gaps between the body and door wooding. I want to add door stops of full length aluminum strips, fastened to the body wood, and overlapping the door gap and part of the door wood. On the door skin wood I want to do some router work...cutting out for lap joints top and bottom...and cutouts along the edges to allow for weather stripping.

Do you have any more info on the momentary switch you plan on using for the headlight dimmer? Doesn't it have to be pretty robust to handle the load? I have a different way to use a momentary switch for my dimmer. My steering wheel has has horn buttons on the spokes, and just a nonfunctional aluminum center cap. If I can mount a momentary switch for the dimmer coming through the center cap, the steering column already has dimmer switch provisions in the harness connector.

Tilt steering wheels are a pet peeve of mine. Generally the tilt takes away from the space between the wheel and the seat, instead of opening up the space. As the wheel tilts, the arc that the bottom of the wheel travels take it closer to the seat, not away from it. Unless the wheel tilts up past being horizontal, you will lose space. Tilting down can give space between the wheel and seat back, but you loose space between the wheel and seat bottom...usually resulting in more contortion, not less. If you are using an aftermarket steering column, the tilting mechanism adds 3-4" to the length of the column, again taking away space...unless you can move the column to compensate. The simplest solution I've seen is a quick release hub, allowing the steering wheel to be completely removed. This works even better if your wheel has more dish.

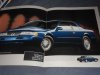

A bit of a near totally irrelevant side note....Around 2 years ago I bought a '95 Cougar used for the dealer showroom brochure photo shoot, based on the mistaken advice that there was an easy way to adapt a quick release hub to make the car useable for me...the factory tilt just makes things worse for me. Now after 2 years of mods trying to get more room between the steering wheel and seat, I've only been able to unsafely drive the car twice. At this point the interior is FUBAR to the point it's uncomfortable to unsafe for normal folk to drive, and it looks it. Hopefully someday soon I'll get over being disgusted with it, and foot the bill to have all the mods undone so it's sellable.

View attachment 11862

My wife would love to be able to ride with me, but it's not destined to be. We're both big folk, and there is no way both of us will fit in that tiny bucket. As is, when I drive it, my only passenger is likely to be my dalmation. Every few weeks or so my wife says something along the lines of me needing to hurry up and get this thing done, because Sassy wants a ride.

If I were starting over with what I know now I'd go for one of RPM's widened and stretched bodies. I'm afraid to ask him what one would cost, because it probably be too tempting to throw away a couple grand in stuff I already have.