You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pics from my build.

- Thread starter rubicon

- Start date

Tjbucket

Member

Finally got my windshield installed. Big thanks to CCR for sending me the thinner material for installing the glass. Big help. also mounted the wind wings. Looking at side mirrors right now not sure where to mount them. I like the oval mirrors from billet specialties a little pricey but they sure do look nice.

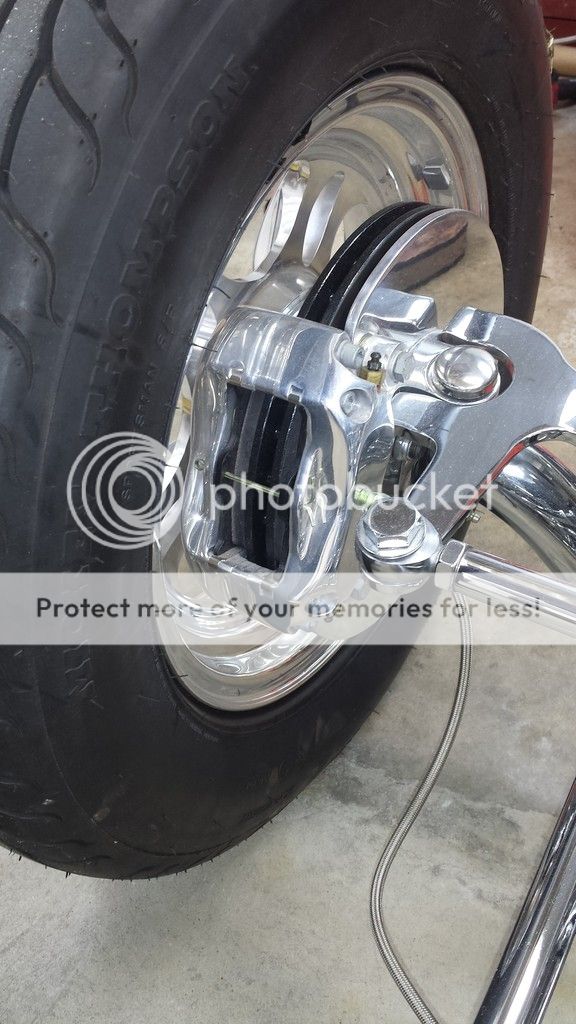

Beautiful job you have done. I used the 3" peep mirror from speedway.....I placed on the brace that attaches the top to the windshield. To be honest they give a nice look, but, are totally useless. I cannot adjust to be useable. Just as easy to turn and look out your rear window, a mirror that small will just be for looks in my opinion. Can you give me a shot of your front brake set up? I am currently running a '42 Ford spindle, with a airheart 175 caliper. Looking to change......but, having a hard time finding the correct mount for a Wilwood caliper.

JeffK

Member

TJ, Try these sites, we used Wilwood brakes on the race car, maybe you can find something here...A-1 RACING PRODUCTS INC., Teo Parts Xpress - Online Shopping - Teo Pro Car - Vernon, New JerseyBeautiful job you have done. I used the 3" peep mirror from speedway.....I placed on the brace that attaches the top to the windshield. To be honest they give a nice look, but, are totally useless. I cannot adjust to be useable. Just as easy to turn and look out your rear window, a mirror that small will just be for looks in my opinion. Can you give me a shot of your front brake set up? I am currently running a '42 Ford spindle, with a airheart 175 caliper. Looking to change......but, having a hard time finding the correct mount for a Wilwood caliper.

choppinczech

Well-Known Member

Hope the pictures help. The front brakes came from CCR. Wilwood brakes.

Clean!

rubicon

Active Member

Started on the paperwork for getting my car titled. First I called the DMV in Madison 1-608-267-2103 and asked to be transferred to the "Research and Information office" There I explained to the lady that I needed a VIN number and Title so I could get my Hobbyist plates. She told me to fill out form MV-1 and MV-2388. Take pictures of all four sides of the vehicle all paperwork of major parts for taxes. Most important is the MSO which I got from CCR. Ill let you guys know how it turns out. I'm not completely done with the car but it is drivable.

Tjbucket

Member

Hope the pictures help. The front brakes came from CCR. Wilwood brakes.

Very nice thank you!

tfeverfred

Well-Known Member

Great to see you're not running into any obstacles with the DMV. Sounds like you're getting positive and timely results.

rubicon

Active Member

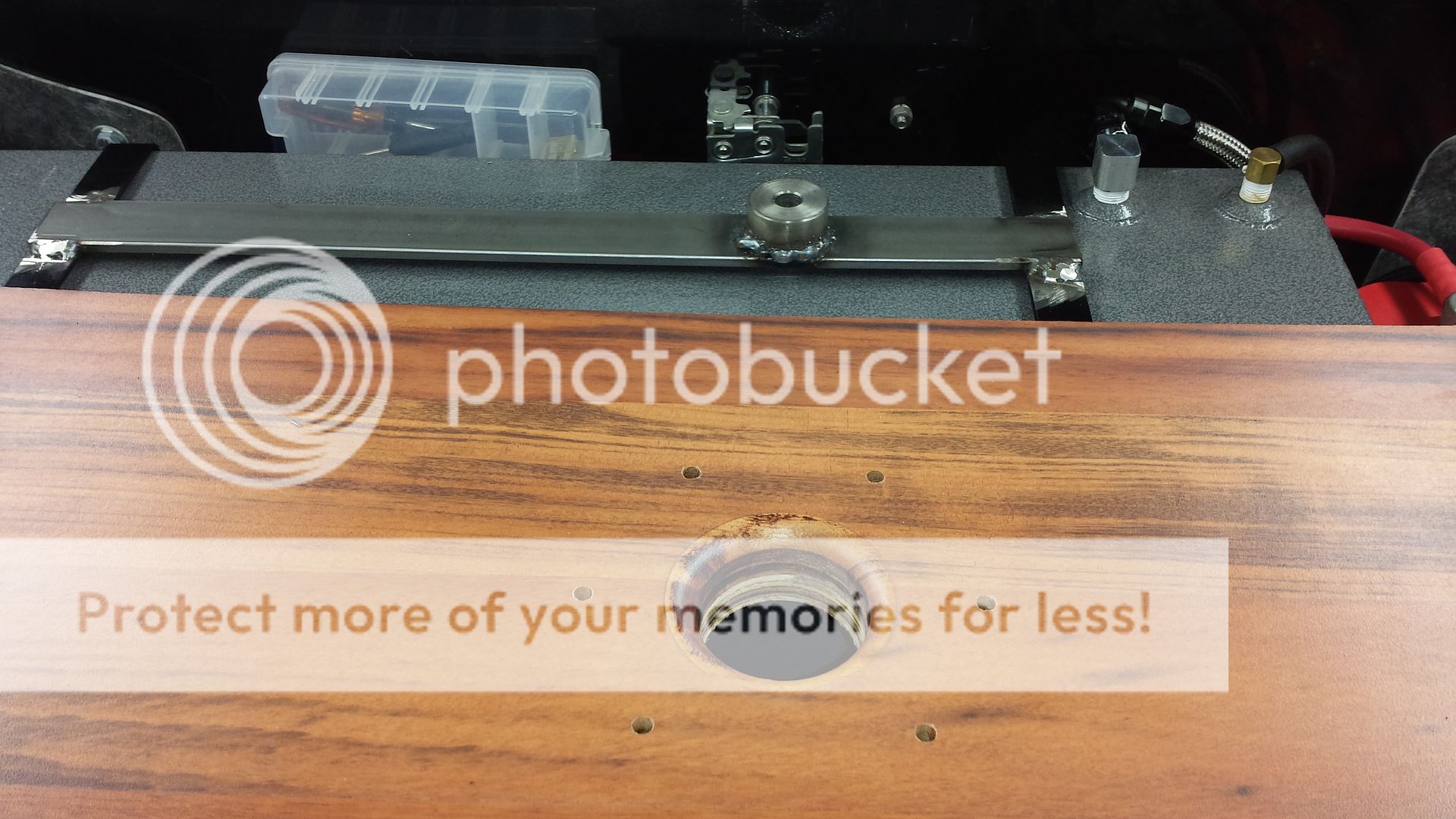

While I wait for my Title and plates, keeping my fingers crossed I have been working on a way to lock my lid on the back. My lid does not open in the upward direction. I have it on draw glides so it moves back to expose the tank and battery. I definitely do not want it to open when I accelerate. I bought a cobra gas cap mounted that on my deck made a bushing to fit inside and ran a locking push pin through to a bung welded to the tank supports. Having trouble with photo bucket again. Will try later to send pics

choppedtop

Well-Known Member

Now that looks great! More of that outside the box stuff.

choppinczech

Well-Known Member

Very slick.

Are you a machinist?

How did you line up the bung center and center of the filler cap?

Are you a machinist?

How did you line up the bung center and center of the filler cap?

rubicon

Active Member

I made the bushing longer and put a piece of tape on top of the gas tank. ran a pencil down the hole and circled the bottom of the bushing. Then I put the cross bar centered over the mark and measure off the tank straps to the edge of the cross strap. This gave me the position to weld the cross strap to the two tank straps. I kept everything square and tack weld. Put the whole bracket back in the car and added tape to the cross strap. Turned off what was needed on the bushing so it would clear the cross bar. Pushed the deck closed. Put lipstick on the end of the ball lock and ran it down the hole to mark where center is on the cross bar tape. Center punch and drilled hole in cross bar. Made bung in lathe and used pin to line up bung on cross bar and tack weld to bar. Put everything together to see how the ball lock fit. It was a little tight so I used hand drill to ream hole out until ball lock went in with a little effort. Finished welding and repeated test fit. The bushing in the cap is aluminum so it is easy to ream. It seemed to work with a little luck. I spent 43 years in a machine shop. Something had to rub off. A big part of my time was testing transmissions for off road equipment. I forgot about the lipstick so I made correction to what I wrote. Don't tell my wife about the lipstick.

Last edited: