You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How I scratch built a Modern T

- Thread starter Tbuilder

- Start date

Tbuilder

Active Member

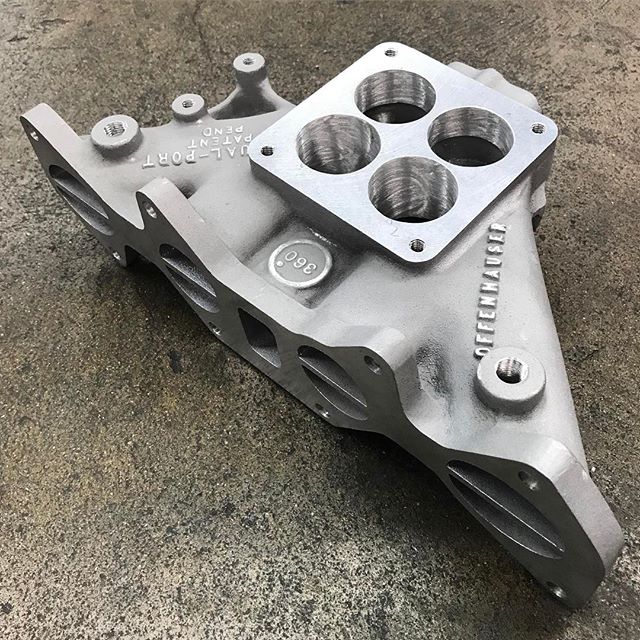

I have an Offy 4bbl manifold that I had on a 74 2300 along with a 390 CFM holly, I'll have to dig deep, I had that car along time ago. I don't know if it would clear your electronic distributor or even fit you head?

The older manifolds will clear the distributor but the bolt pattern is different. The one you have probably looks similar to this one.

fletcherson

Well-Known Member

Did they change the port design too? Why not just run the fuel injection?Yea, but instead of that 2bbl. pad, it has a pad for the small 4bbl, like this...

Tbuilder

Active Member

Yes, the new ports are D shaped (flat bottom). The bolt pattern is wrong, on the newer engines the top bolt is forward and the bottom is back. In the pic the second port is correct the rest are backwards. I suppose in thinking about it now I could redrill and tap the holes and get the old manifold to fit but that would be a lot of work, still might not fit and would require buying another manifold and carb. It will be easier to just build a new manifold.

All the systems to control the fuel injection and ignition are gone.

All the systems to control the fuel injection and ignition are gone.

Kevinrevin

Member

Esslinger Engineering - Chino, California | Esslinger racing | Ford Race Engine | Performance Parts | Duratec |Ecoboost | MZR Esslinger Engineering | Esslinger racing has the intake you need.....and a lot of other things you want.

I used,e otfthwor intakes & camshaftin my Pinto dirt car years ago. That engine screamed with the Holley 650 cfm Annular Discharge carb.

Esslinger has lots of knowledge regarding the 2300 Ford engine.

I used,e otfthwor intakes & camshaftin my Pinto dirt car years ago. That engine screamed with the Holley 650 cfm Annular Discharge carb.

Esslinger has lots of knowledge regarding the 2300 Ford engine.

Tbuilder

Active Member

Setting aside the engine problems for now I took the time to paint all the body parts. The bucket, turtledeck, engine hood and rad cowl will be painted blue and the fenders, running boards and splash pans will be painted black.

I decided to buy the paint from Summit Racing, their paint system had good reviews and compared to some was priced reasonably. Painting is expensive! Not knowing any better I ordered some of the most difficult colors to put on. Black Starburst Pear and Ultra Blue Pearl.

I also ordered a good DeVilbiss HLVP spray gun with a set of different size nozzles

I decided to paint each of the blue body parts separately starting with the bucket itself then the turtledeck, hood and rad cowl together. I did black parts in one set up each for the front fenders, the rear ones next then the splash pans and the rest of the small parts.

The painting came out pretty good considering my lack of experience. It took quite a bit of messing around to get the air pressure and the gun set correctly. The blue went on well but the black gave a lot of problems as I could not get it to flow out nice. With the changes in temp and humidity from one day to the next I had trouble making the required changes to the paint mix and gun settings. But after a couple of times of having to sand it down and do it over it finally turned out well.

I decided to buy the paint from Summit Racing, their paint system had good reviews and compared to some was priced reasonably. Painting is expensive! Not knowing any better I ordered some of the most difficult colors to put on. Black Starburst Pear and Ultra Blue Pearl.

I also ordered a good DeVilbiss HLVP spray gun with a set of different size nozzles

I decided to paint each of the blue body parts separately starting with the bucket itself then the turtledeck, hood and rad cowl together. I did black parts in one set up each for the front fenders, the rear ones next then the splash pans and the rest of the small parts.

The painting came out pretty good considering my lack of experience. It took quite a bit of messing around to get the air pressure and the gun set correctly. The blue went on well but the black gave a lot of problems as I could not get it to flow out nice. With the changes in temp and humidity from one day to the next I had trouble making the required changes to the paint mix and gun settings. But after a couple of times of having to sand it down and do it over it finally turned out well.

Tbuilder

Active Member

I made a gas tank out of .050 5051 aluminum sheet. I cut out two pieces. The top and both sides for one piece and the bottom and both ends for the other. I then bent the ends 90 deg in a sheet metal brake, fitted it and had a friend tig weld them together. We welded a boss for the fuel cap and guage and two smaller ones for the fuel pickup and vent line. By my calculations it should hold ten gallons of fuel.

I bolted the newly painted body to the frame, installed the gas tank then bolted the turtle deck in place. At this point I decided to leave the fenders off while I installed the electric fuel pump, fuel lines, brake lines, emergency brake cables and did the wiring.

One of the bad things about the fenders is they get in the way when you are trying to work on the other parts of the car. Leaning over them trying to reach the engine and body is really hard on an old mans back.

The tank inside the turtle deck. Still have enough room for a case of beer.

I bolted the newly painted body to the frame, installed the gas tank then bolted the turtle deck in place. At this point I decided to leave the fenders off while I installed the electric fuel pump, fuel lines, brake lines, emergency brake cables and did the wiring.

One of the bad things about the fenders is they get in the way when you are trying to work on the other parts of the car. Leaning over them trying to reach the engine and body is really hard on an old mans back.

The tank inside the turtle deck. Still have enough room for a case of beer.

choppedtop

Well-Known Member

Little Daddy, Ed Roths son, was at the Starbird show in Tulsa this year. He had a stripping booth and was selling his new paint. He told some pretty good stories about being a kid with BD as his dad.

old round fart

Well-Known Member

I’m sure all his stories were just as it was too! Lol

Tbuilder

Active Member

I got the pushrods for the brake master cylinder and the clutch master cylinder installed and working. I installed a proportioning valve and got all the brake lines hooked up and bled.

The line from the clutch master cylinder was too long and made of a hard plastic material that no matter how hard I tried I was not able to splice it without it leaking. I finally ended up making a length of brake line hose fit. No matter how many times I bled it the clutch would not disengage. I replaced all the parts in the master cylinder and it still would not work, so the problem had to be in the slave cylinder/throwout bearing unit.

Yeah, I know, I should have replaced it when I checked the clutch.

Now I have to pull the engine to replace it.

The line from the clutch master cylinder was too long and made of a hard plastic material that no matter how hard I tried I was not able to splice it without it leaking. I finally ended up making a length of brake line hose fit. No matter how many times I bled it the clutch would not disengage. I replaced all the parts in the master cylinder and it still would not work, so the problem had to be in the slave cylinder/throwout bearing unit.

Yeah, I know, I should have replaced it when I checked the clutch.

Now I have to pull the engine to replace it.

Tbuilder

Active Member

Why not keep it computerized with the fuel injection and electronic ignition?

I did not want to go through all the hassle of trying to get all the wiring, electronics and sensors hooked up and working in a place they were not designed to be in, besides I wanted it 'old school', carbs, easy to figure out and work on.

Tbuilder

Active Member

Back to the intake manifold. I cut out a manifold flange from some mild steel 3/8” plate using the intake gasket as a pattern. Some trial and error determined that 1 5/8” diameter exhaust pipe fits the intake flange hole almost perfectly with a little hammer forming to fit it to the D shape. I used two 1 5/8” short radius U bends that I had in stock, cut them in half, fitted them to the flange and angled them up to make a sort of tunnel ram manifold. I fabbed a box shaped plenum from some 1/16” steel and welded it to the four tubes. The top of the plenum was cut out to fit two Holly 94 carbs that I had from an old project that never got finished. I made it as compact as I could but with the air cleaner on top it still came out a little higher than I liked. I added a fitting to it for the distributor vacuum advance.

It turned out ok, looks like it should work but we will see when we get the engine running.

It turned out ok, looks like it should work but we will see when we get the engine running.

Similar threads

- Replies

- 4

- Views

- 961

- Replies

- 4

- Views

- 280