You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Keepers build

- Thread starter Keeper

- Start date

Keeper

Active Member

Keeper

Active Member

Now that I have the seats sorted out I can finally mount the steering wheel in its final location.

I went with Ted's advice on the mount using 1/4 plate and 4 bolts. The column I am using is out of a early 70's Lincoln/Ford. It has a collapsible shaft in the column allowing for the ability to create a telescopic column it also has tilt. With that in mind I went to the metal store to pick up some 2 1/4 ID 1/8 wall pipe. This will allow the stock column to slide into the mount.

Not a lot to it. Once I found the angle I wanted I tacked in the pipe to check before final welding.

Here you can see how the column will allow for some in/out adjusting. I set it up to only allow for about 2 inches of adjustment, but that is plenty to make up the difference between where I like the wheel and where my wife liked it.

There will be a pin installed in the original column that will ride in a slot cut in the pipe, this will serve two purposes, one to keep the wheel centered, and two to limit the amount of adjustment. Once I have it finalized I will post more pics.

After I got the column mounted, I finalized the brake pedal location. Then I drilled/bolted the pedal to the arm. I started working on the foot rest, but got called in for dinner!

Couple small projects that I can check off the list.

I went with Ted's advice on the mount using 1/4 plate and 4 bolts. The column I am using is out of a early 70's Lincoln/Ford. It has a collapsible shaft in the column allowing for the ability to create a telescopic column it also has tilt. With that in mind I went to the metal store to pick up some 2 1/4 ID 1/8 wall pipe. This will allow the stock column to slide into the mount.

Not a lot to it. Once I found the angle I wanted I tacked in the pipe to check before final welding.

Here you can see how the column will allow for some in/out adjusting. I set it up to only allow for about 2 inches of adjustment, but that is plenty to make up the difference between where I like the wheel and where my wife liked it.

There will be a pin installed in the original column that will ride in a slot cut in the pipe, this will serve two purposes, one to keep the wheel centered, and two to limit the amount of adjustment. Once I have it finalized I will post more pics.

After I got the column mounted, I finalized the brake pedal location. Then I drilled/bolted the pedal to the arm. I started working on the foot rest, but got called in for dinner!

Couple small projects that I can check off the list.

Keeper

Active Member

If you don't like the looks of the bolt ends and nuts use 'T-nuts" on the outside of the firewall. You can find them at most building centers with a good fastener section.

Ron

I thought about those, do they make different grades? Like grade 5 or 8?

Yeah the gas pedal will be interesting to fit, I am pretty sure it will be sitting over the tunnel, or at least close to the edge.

I may change out that brake pedal for a smaller one, its a bolt on pedal so I can swap it out.

For comfort yes ditch the pedal and go with a round one.The gas pedal will be over the tunnel how far?depends if either of you drive righty,lefty.right gas left brake.I'm trying to concoct a pad for my foot to rest on still working on it.When you figger it out post some pics.I thought about those, do they make different grades? Like grade 5 or 8?

Yeah the gas pedal will be interesting to fit, I am pretty sure it will be sitting over the tunnel, or at least close to the edge.

I may change out that brake pedal for a smaller one, its a bolt on pedal so I can swap it out.

EX JUNK

Moderator

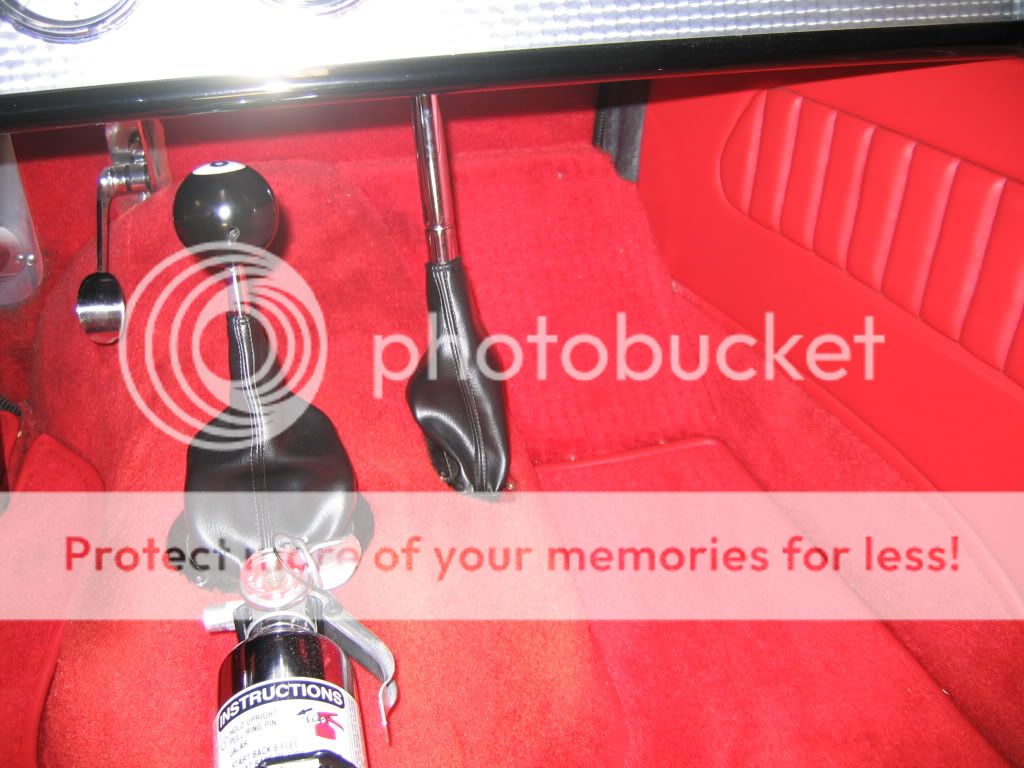

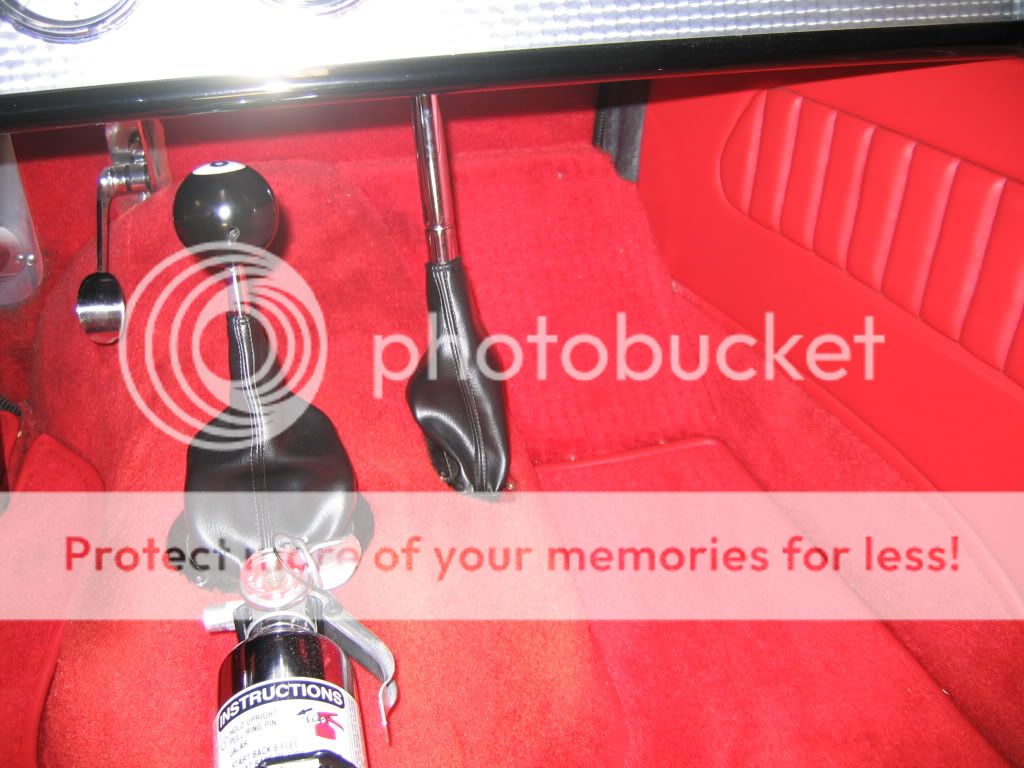

Keeper, Maybe this will give you some ideas.

As a further note, my dimmer switch is mounted on the aluminum plate above the column. It is reached very easily and as a whole a VERY comfortable car to drive for extended periods.

Jim

P.S. I drive AND brake with my right foot ONLY.

As a further note, my dimmer switch is mounted on the aluminum plate above the column. It is reached very easily and as a whole a VERY comfortable car to drive for extended periods.

Jim

P.S. I drive AND brake with my right foot ONLY.

I have been using 'T nuts" for a long time and have yet to have a failure. I have even used them as nut plates for things like tail light mount thread inserts in frame rails.

Another idea for a foot reat for your left peg is to make up acopy of your brake pedal, weld it to a plate and bolt it to the floor. It looks like a clutch set up then.

Ron

Another idea for a foot reat for your left peg is to make up acopy of your brake pedal, weld it to a plate and bolt it to the floor. It looks like a clutch set up then.

Ron

Opps sorry i thought you were talking about your Right foot on the trans hump.I just put my left foot on the floor as far as it will go the right foot is a pain cause you have to balance your foot half way up the hump.I have been using 'T nuts" for a long time and have yet to have a failure. I have even used them as nut plates for things like tail light mount thread inserts in frame rails.

Another idea for a foot reat for your left peg is to make up acopy of your brake pedal, weld it to a plate and bolt it to the floor. It looks like a clutch set up then.

Ron

EX JUNK

Moderator

Opps sorry i thought you were talking about your Right foot on the trans hump.I just put my left foot on the floor as far as it will go the right foot is a pain cause you have to balance your foot half way up the hump.

Rick, if you notice in my pictures, my right foot is in the "normal" position with my heel resting on the floor. This makes for a very comfortable driving position just like in your every day driver. Ergonomics is very important in any of my builds.

Jim

Jim i messed up when i put my pedal in i put it to far over the hump and now i pay the price i have to kind of ballance my foot.Rick, if you notice in my pictures, my right foot is in the "normal" position with my heel resting on the floor. This makes for a very comfortable driving position just like in your every day driver. Ergonomics is very important in any of my builds.

Jim

Similar threads

- Replies

- 26

- Views

- 9K