Ted Brown

Member

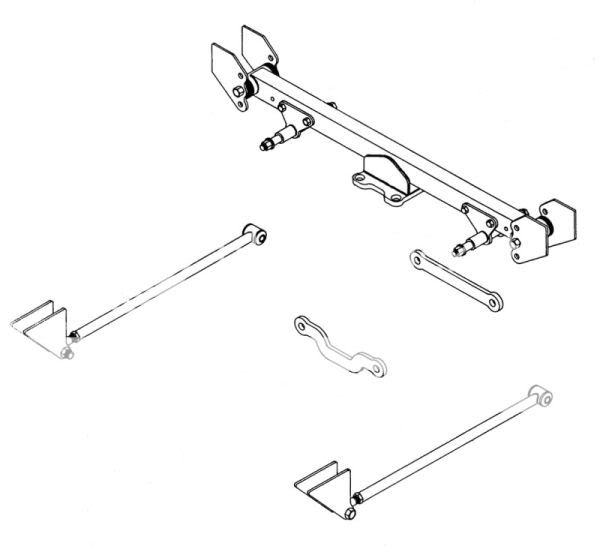

I sure wish people would mount a Jag, just like the factory, only you can make it look trick, but work just as well or even better, not solid like my plans say to do, I found that I was way off base when I first did them that way... There is so very much leverage with big tires and the pinion, that are both trying to rotate that third member, and in two different directions, both sideways/twisting and forward and back... Buy running the lower braces at least straight forward, you are helping to keep the third member from taring itself loose from the frame and the mounting plate, and I said to use 3/8" plate for that third member mounting plate, I was wrong! in a solid mount, that is not near strong enough (if you are going to drive a T Bucket, near as hard as I drive mine) 5/8" would be a bit better, but I still would change everything and mount it all with rubber type (big 4 bar bushings or big rear spring bushings) and a strong either single or hairpin type rear radius rod (like the factory uses a flapper arm/bar, what I call a flapper bar, but a strong radius rod, none the less) as the lower radius rod will now keep the whole setup from twisting forward and breaking the rubber mounts, when on the load pedal, only the small movement from the bushings, and this movement will make that whole system live... and the stock Jag housing/tin cover also has travel stops that the outer Alum flange carriers,,, these stops bottom out on, BEFORE the U joint gets to that bad bind point of no return, or failure... I hate to admit that I have had to fix a few of my own jobs over the years for this very reason, as they say, drive them and learn, sometimes the HARD way!