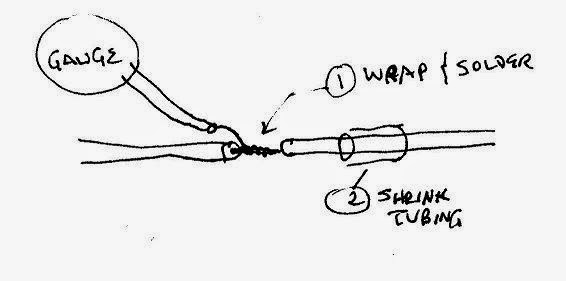

I do an inline splice:

...use a strip tool to make a 1/2" gap in the insulation of the common wire, then wrap the gauge wire around it and solder. Then slide the tubing over the joint and shrink. Daisy-chain to all gauges, and the common wire ends in the connector.

You might be able to tell, but if not ...... I used your idea for running all those

common wires for lights and ground ...etc.

My drawings show a cutoff switch to shutdown all electrical, I had to leave

that out. There was just NOT enough room for it. I also nixed the idea of

having 4-way flashers, it was going to complicate and already complicated

wiring system.

Now some good news, the dash wiring is done. I still have to bring the wires

up to the dash and terminate them in the other side of the connectors you see.

I had to buy a different Deutsch DTM series or mini size connectors and

crimping tool for the dash. Many of the wires are 20 AWG and smaller and

the DT series will not go that small, only down to 18 AWG.

I use heat shrink in different colors to identify certain bundles of wires from

others. When I don't have what I need then I use a SHARPIE to add a band to

each segment of heat shrink.

I used plenty of Adel clamps to support the wires and keep them from moving

around while driving and causing a fatigue failure.